新着情報

―

2024-03-22

エコアクション21 中間審査認証[会社情報]

2024-03-01

2025年度 新卒採用のエントリー受付中! [新卒採用]

2024-02-22

QMS第7-2回定期維持審査[会社情報]

| もっと見る |

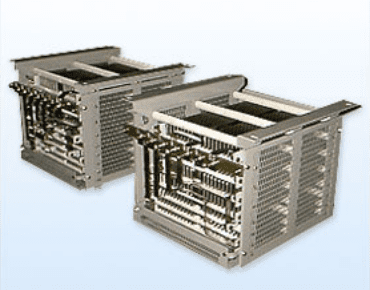

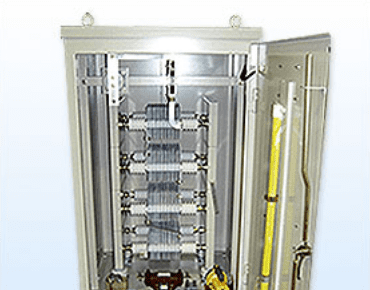

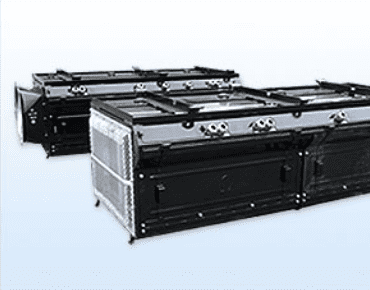

製品案内

―

ご依頼の流れ

―

お客様のご要望に可能な限り沿う形で各種抵抗器の設計・提案をさせて頂きます。

ご要望のヒアリング

抵抗器の用途や設置スペースなどのご希望をお聞かせください。

設計・ご提案

豊富な経験からお客様のご満足のいくご提案をいたします。

製作・加工

ご提案しご納得いただけた設計を元に製作・加工を行っていきます。

完成検査

完成した抵抗器を細かく検査いたします。

納入

無事検査を終えた製品をお客様先に納入いたします。

採用情報

―

これから初めて働く方も、経験のあるベテランの方も、自分ができることに積極的に取り組めば、新たなチャンスを創り出すことができます。より良い仕事を目指せる仲間を募集しています。

お問い合わせ

―

お問い合わせ・お見積りは電話とFAXとメールフォームより承っています。

FAXとメールフォームは内容を確認後、折り返し当社営業より連絡させて頂きます。

FAXとメールフォームは内容を確認後、折り返し当社営業より連絡させて頂きます。